A standalone company focused on sustainable solutions

Copeland is now a standalone company. As the global leader in providing sustainable heating, cooling and refrigeration solutions, we’re helping residential, commercial and industrial customers reduce their carbon emissions and improve energy efficiency.

提升技术让世界变得更加美好

从我们每天在家享用的食物、至室内的舒适环境,谷轮 压缩机是暖通空调及制冷系统的核心,深得业主、企业和工业所信赖。谷轮与其他压缩机品牌比较,受到更多暖通空调及制冷专业人士的爱戴。我们所有产品的设计、制作及测试,确保无以伦比的可靠性及运作宁静。我们更不断研发,改进技术,以满足今日客户对能源和环境标准要求。这正是更多暖通空调及制冷专业人士指定选用谷轮,而非其他压缩机品牌的原因。屡获殊荣的谷轮™涡旋技术致力为全球带来更舒适凉快的环境,打造行业标杆。

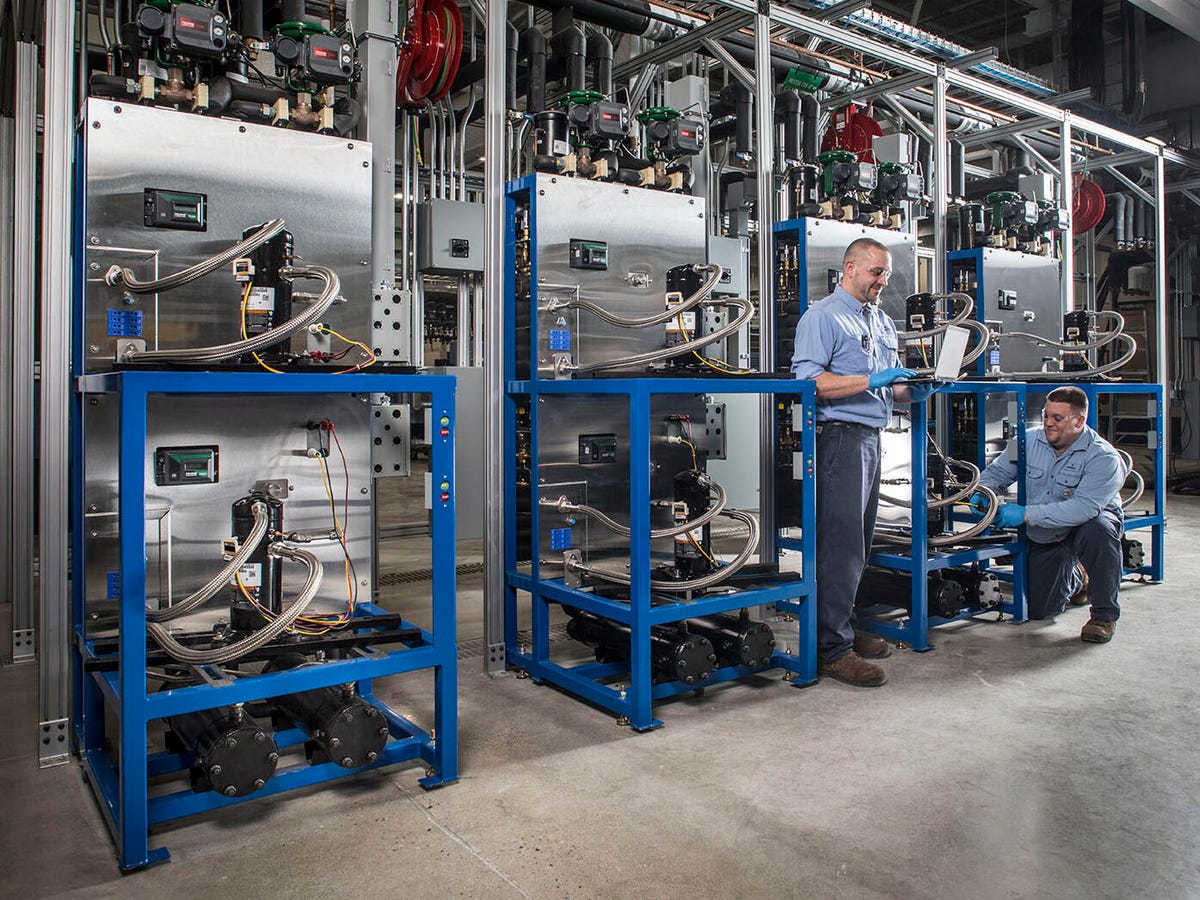

Tomorrow’s Compressors Today

The future of HVACR is full of uncertainties: new regulations, new products and new realities. Developing HVAC and refrigeration systems that meet new efficiency and refrigerant regulations can present a new set of complex challenges. Our next-gen Copeland scroll technology has been designed for maximum efficiency and a full range of low-GWP refrigerants and comes complete with smart features like plug-and-play electronics to provide the performance and flexibility you need for regulation-ready system design. Beyond our next-gen Copeland compressors that live at the heart of HVAC and refrigeration systems that homeowners, businesses and industries have depended on, our industry-leading expertise and training programs can help you determine what upcoming changes mean for your business while helping you get prepare for tomorrow’s challenges today.

谷轮™涡旋科技

谷轮率先在压缩机中使用涡旋技术,从此改变了业界。谷轮™涡旋科技自此一直领导暖通空调行业,其效能卓越,可靠,安装简易优势,深得承包商和原始设备制造商一致推崇。

How does a scroll compressor work?

Copeland scroll compressors work with one scroll orbiting in a path defined by a matching fixed scroll. The fixed scroll is attached to the compressor body while the orbiting scroll is coupled to the crankshaft. The orbiting motion creates a series of gas pockets traveling between the two scrolls. On the outer portion of the scrolls, the pockets draw in gas then move it to the center of the scroll where it's discharged. As the gas moves into the scroll's center, the temperature and pressure increase to the desired discharge pressure.

Watch the video to learn more: