Visit Vilter booth #229 to experience how our sustainable industrial solutions improve lives and protect the planet, today and for future generations.

At Copeland, we are committed to creating groundbreaking innovations across cold chain, commercial, industrial, and residential markets by aiding the refrigerant transition and improving energy efficiency on a global scale.

What’s new, What’s next: Join us in-booth for the following sessions

Attend one of our sessions for the chance to receive a Stanley mug.

CO2 reimagined: How technology enables cost-effective installations

Single screw compressor technology enables a simple approach to large industrial CO2 installations.

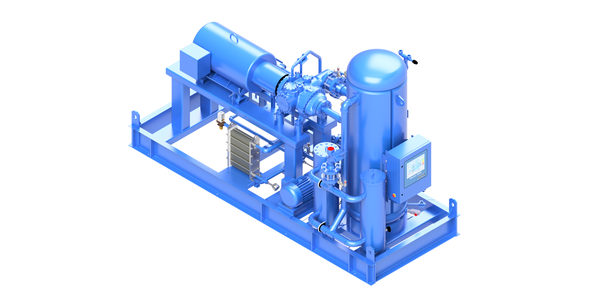

See it first: Standard-skid heat pump accelerates energy transition

Simple design with a single screw compressor increases durability, reliability and performance in industrial spaces.

The inside story on durability: How unique technology delivers performance-enhancing reliability in ammonia applications

Learn about the unique design elements that balance the damaging forces seen by screw compressors, helping reduce maintenance demands.

CO2 simplicity: get your system configured in less than 20 minutes

Stop by our booth to connect with our experts and have your CO2 system configured.

Our configurator will narrow down hundreds of options to a design that fits your specific needs for output and performance.

Featured products

Leading the way with refrigeration and heat pump technology that supports natural refrigerants; including CO2 and Ammonia

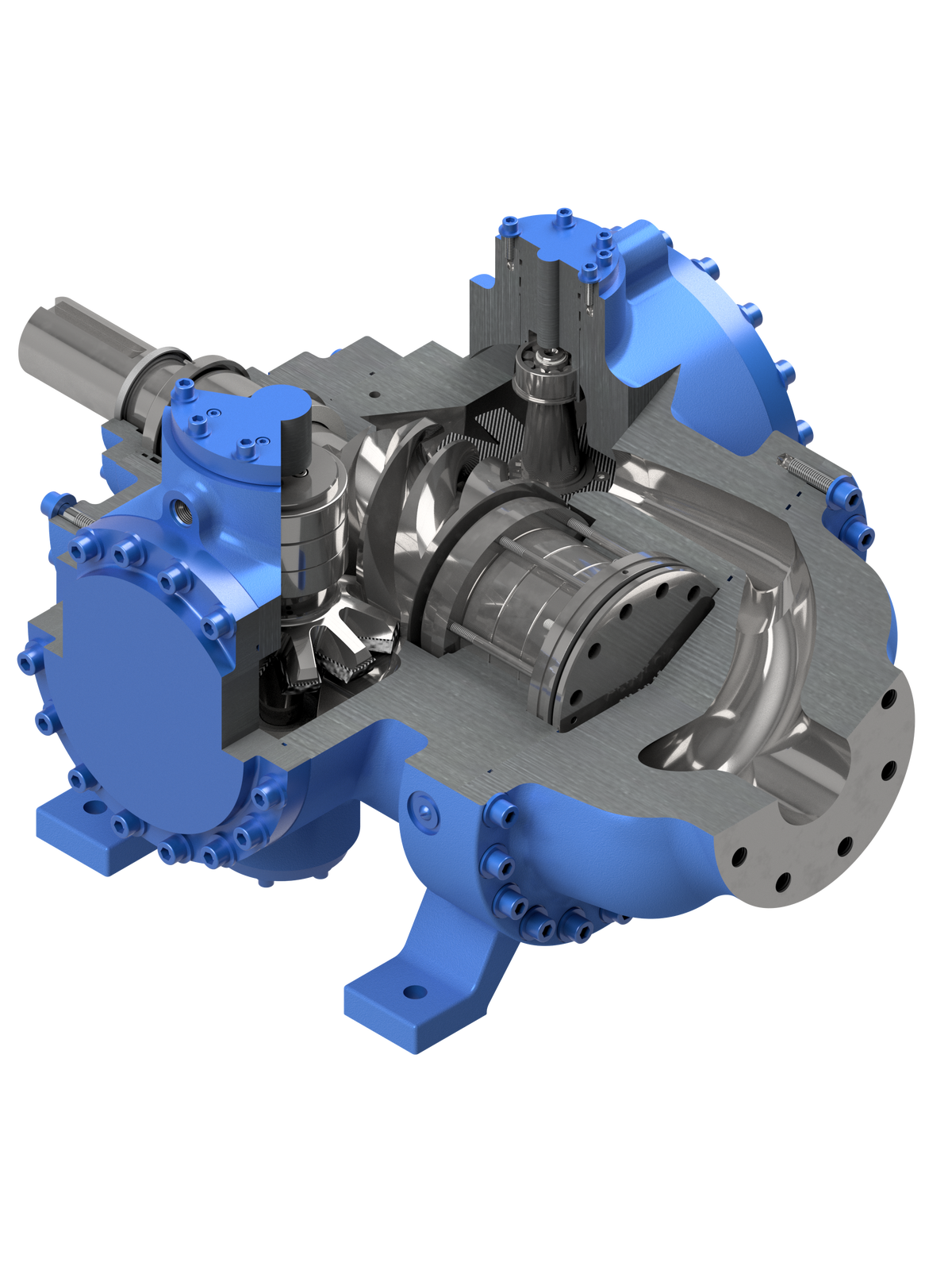

Leading single screw technology

Our transformational solutions are powered by the efficient Vilter single screw compressor, which enables industry leading up-time over decades of operation.

- Balance of axial and radial loading extends bearing lifespan for improved durability

- Precision mechanical modulation of capacity and pressure ratio through Parallex Slides enhances operational flexibility

- Tolerance to liquid droplets eliminates the need for superheat, boosting COP

- Simplified servicing ensures hassle-free maintenance

- Proven resilience in the most challenging environments, ensuring reliable performance

- Extensive 15-year track record of operating in heat pump duty at temperatures of up to 90°C, demonstrating robustness and longevity

Vilter training

Learn from our experts how to maintain and service Vilter industrial compressor equipment with hands-on technical training from a certified staff.