Ideal Form, Fit and Function

Simplify Operational Complexities

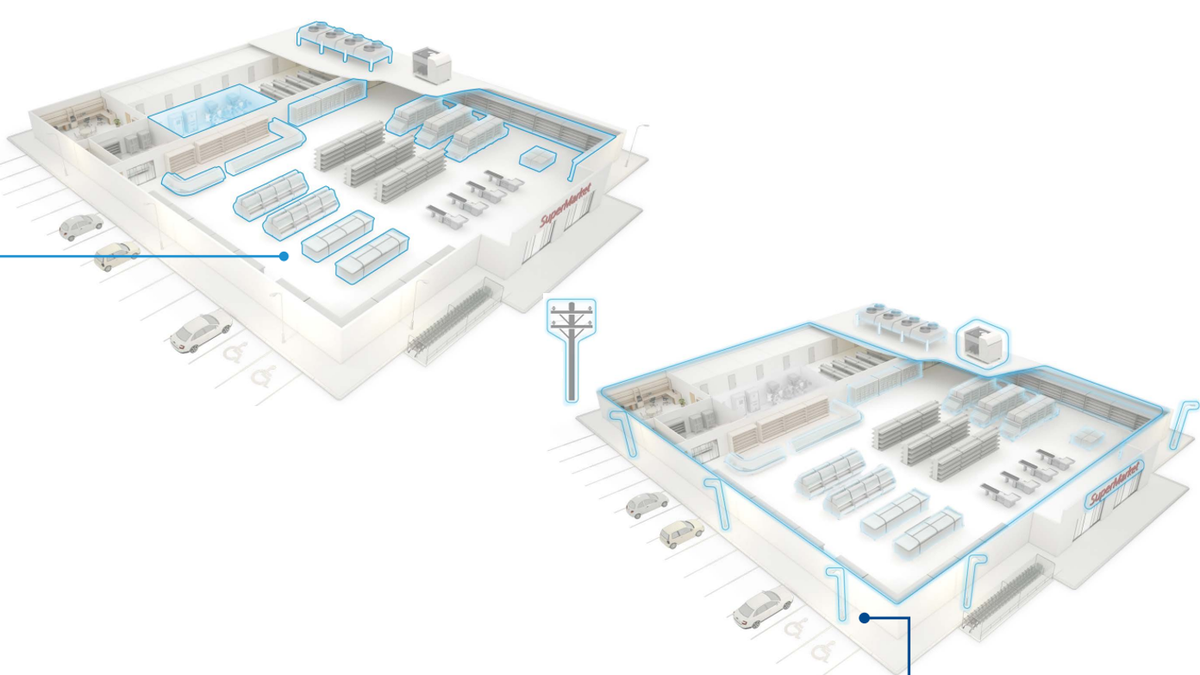

The all-new E3 controller builds upon the foundation of the industry standard E2, adding a built-in touch-screen display and integration with Copeland's supervisory control software. This significant upgrade delivers a user-friendly, web-accessible interface that enables control over critical building and refrigeration systems, including: compressor groups, condensers and walk-in units, HVAC and lighting systems — all while giving end users a true, drop-in replacement for their E2.

E3 Control Delivers Upgraded Capabilities

Having an E3 controller at the control helm of refrigeration and HVAC systems provides multiple advantages to technicians, end users and OEMs. Many modern retailers are understanding the importance of having a building and/or energy management system, and the E3 controller provides these robust capabilities while streamlining individual system control. To learn more about how the E3 supervisory control simplifies servicing and delivers robust system management and control, check out our article.

E3 Supervisory Control for CO₂ Applications

The E3 controller for CO2 applications is part of Copeland's next generation of facility management and refrigeration control platform. This CO2-specific version of the E3 controller streamlines management of essential facility systems and provides advanced CO2 supercritical booster refrigeration control in an easy-to-use platform.

Product Spotlight Webinar

Learn more about our E3 supervisory control platform with subject matter experts in the Food Retail & Digital Solutions business at Copeland. Gain insights into the following topics:

- How our supervisory control software brings all supervisory control devices under one software interface

- Why the E3 was designed as a true drop-in replacement of the E2

- How to gain instant visibility to all key systems, faults, statuses, and alarms

- How our supervisory control platform enables control of critical systems with advanced refrigeration algorithms, building control strategies and network connectivity

case study

We donated a control system equipped with the all-new E3 controller to monitor and maintain the combination walk-in cooler/freezer system at a new facility for the Food Bank of Alaska in Anchorage. The E3 enables on-site or remote access to two outdoor condensing units (OCUs) and four indoor evaporators for the cooler; three OCUs and six indoor evaporators for the freezer; plus two leak detection systems. This next-generation setup builds on the proven success of the industry-standard legacy E2, with the addition of a user-friendly, web-accessible interface.

“With E3 and Site Supervisor, you can simply go to one source and gain a lot of information on what your unit’s actually doing... I think the E3 will reduce the initial cost of any maintenance call, simply because the technician won’t have to go to multiple locations throughout the facility to track down several issues.”

Vice President of Construction Operations

Raise Your Standard to the Power of Three

- TRUE DROP-IN REPLACEMENT

- VISUAL STORE MANAGEMENT

- ROBUST CONTROL CAPABILITIES

True drop-in replacement

With the same form, fit and wiring that is designed to fit into your existing E2 panels, the new E3 provides a true drop-in replacement for simplified installation.

Visual store management

Gain instant visibility to all key systems in your store and quickly identify problem areas. Includes floor plan views, graphic status indicators and smart alarms.

Robust control capabilities

Take control of all critical systems with greatly expanded refrigeration control strategies, suction control algorithms, building controls and network connectivity.