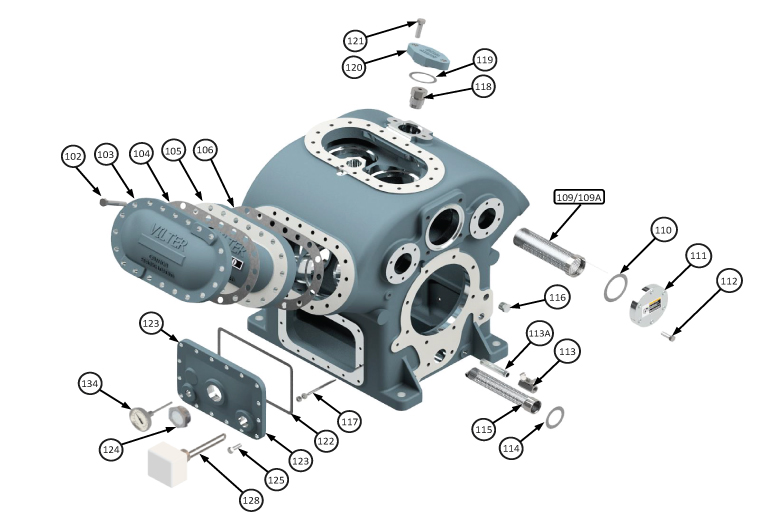

- BASIC FRAME & COVERS

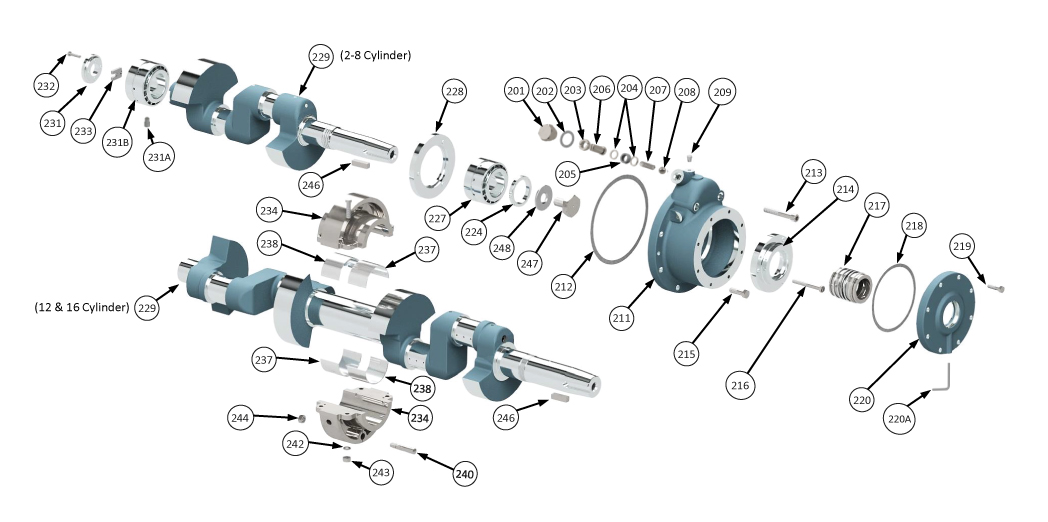

- CRANKSHAFT & FRONT BEARING COVER

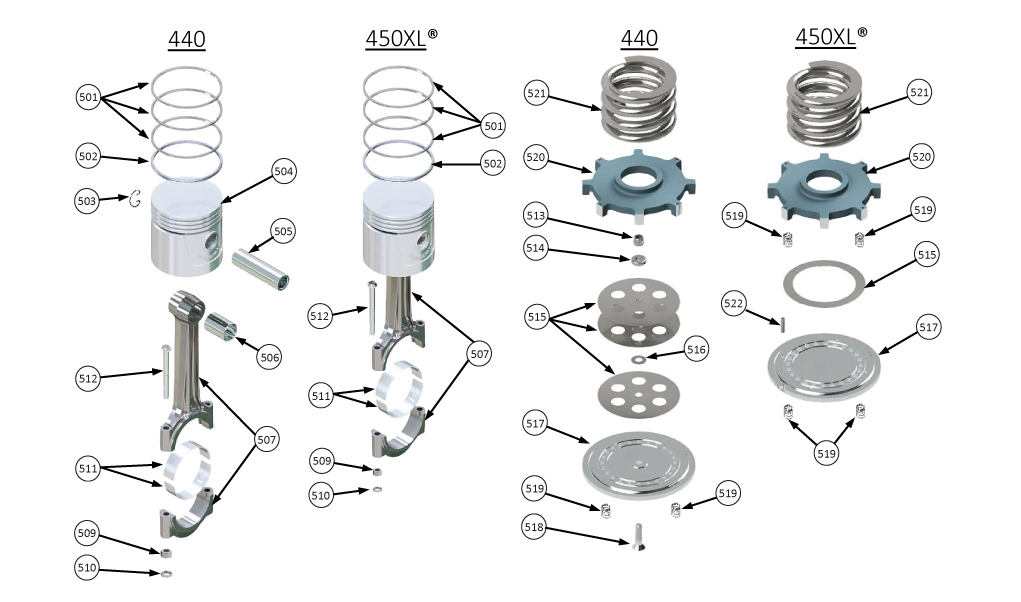

- PISTON, CONNECTING ROD & SAFETY HEAD

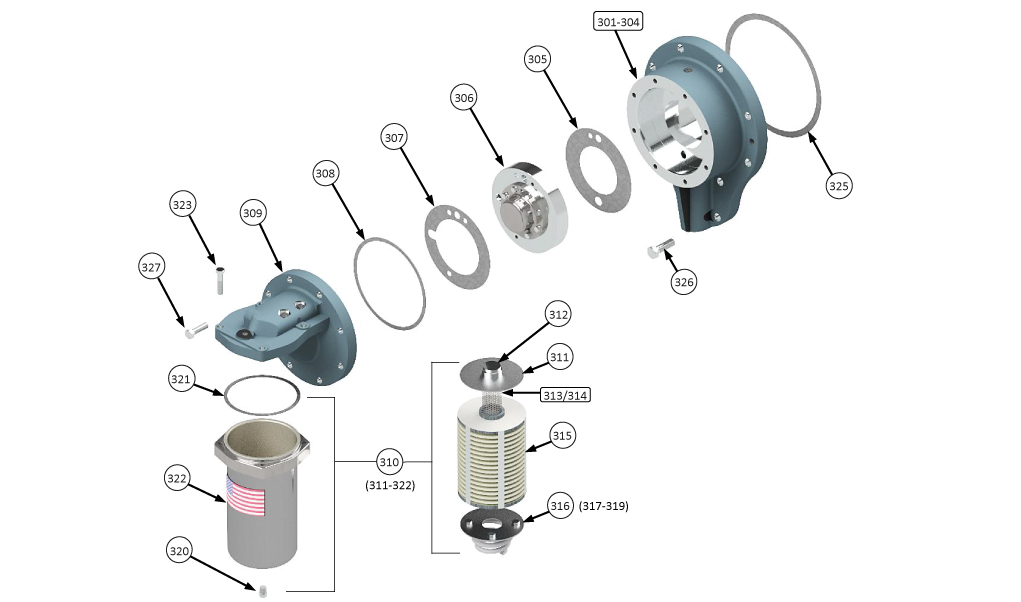

- REAR BEARING COVER & FILTER ASSEMBLY

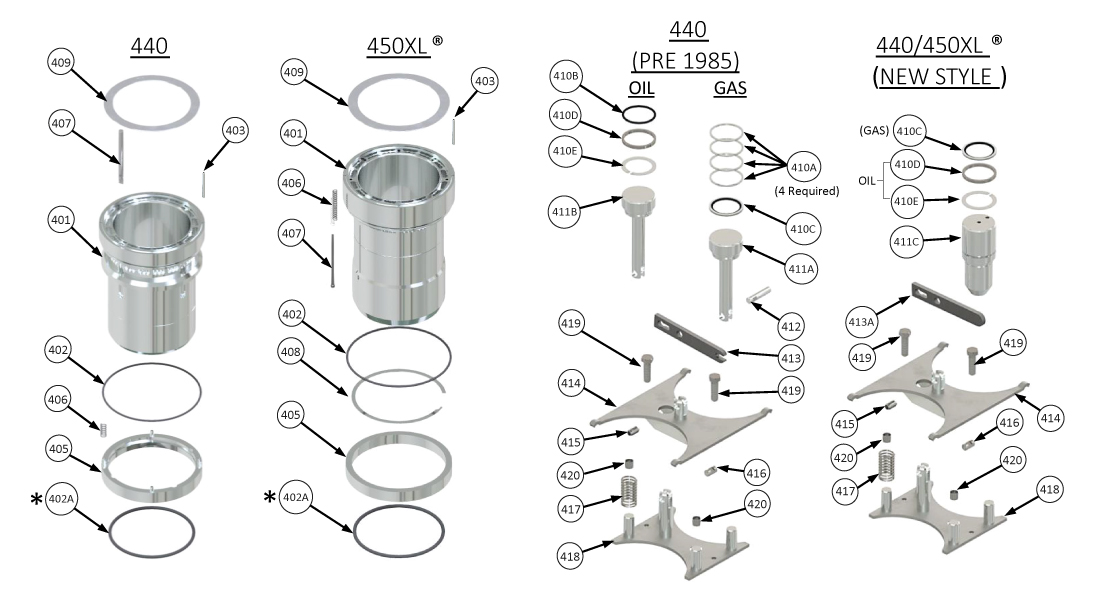

- CYLINDER LINER & CAPACITY CONTROL

| Reference Number | Vilter Part Number | Description | |

|---|---|---|---|

| 440 | 450XL | ||

| 102 | 13152G | 13152G | Screw, 5/8" X 2-1/2" Hex. Head Cap (Used w/o Water Jacket) |

| 102 (a) | 13152L | 13152L | Screw, 5/8" X 3-1/2" Hex. Head Cap (Used with Water Jacket) |

| 103 | 30299A | 30299A | Cover, Water Jacket |

| 104 | 33329A | 33329A | Gasket, Water Jacket |

| 105 | * | * | Cover Cylinder |

| 106 | 33330A | 33330A | Gasket, Cylinder Cover |

| 109 | * | * | Screen, Suction |

| 109A | * | * | Bag Suction Screen ( Not Shown) |

| 110 | * | * | Gasket, Suction Screen/ Suction Tee Cover |

| 111 | * | * | Cover, Suction Screen Cover Suction Tee |

| 112 | * | * | Screw, Hex Head Cap |

| 113 | 1956H | 1956H | Valve, 1/2" Oil Charge and Drain (Ammonia) |

| 113 | 1956A | 1956A | Valve, 1/2" Oil Charge and Drain (Halocarbon) |

| 113A | 13189G | 13189G | Nipple 1/2" X 4" Sch 80 Pipe |

| 114 | 31889A | 31889A | Gasket, Crankcase Oil Screen |

| 115 | A31886A | A31886A | Screen, Crankcase Oil |

| 116 | 13264D | 13264D | Plug, 1/2" Hex. Head Pipe |

| 116 | 13264E | 13264E | Plug, 3/4" Hex. Head Pipe |

| 117 | A31936A | A31936A | Pin Retaining Assembly For Crankcase Oil Screen |

| 118 | 1721B | 1721C | Safety Valve, Internal Relief |

| 119 | 11323G | 11323G | Gasket, 2" Flange |

| 120 | 31954A | 31954A | Cover, Safety Valve |

| 121 | 13152E | 13152E | Screw, 5/8" X 2" Hex Head Cap |

| 122 | 31894A | 31894A | Gasket, Handhole Cover |

| 123 (b) | * | * | Cover, Handhole |

| 124 | 1484A | 1484A | Glass, Oil Sight- 2" |

| 125 | 2796E | 2796E | Screw, 1/2" X 1-1/2" Hex Head Cap |

| 128 | * | * | Heater, Crankcase Oil |

| 134 | * | * | Thermometer, Crankcase Oil |

(a) Use VPN 13152M (Screw, 5/8" X 3-3/4" Hex. Head Cap) for four bolt hole locations at raised face on Water Jacket.

(b) There are different versions of Handhole cover. Handhole cover for 3” sight glass is not available (compressors with serial number starting from 0 thru 13049).

* Check your Operator‘s Manual for correct Part Number for your specific compressor model.

| Reference Number | Vilter Part Number | Description | |

|---|---|---|---|

| 440 | 450XL | ||

| 202 | 30651C | 30651C | Cap, Valve Gasket |

| 201-208 | KT486 | KT486 | Oil Relief Valve Kit |

| 209 | 13264B | 13264B | Plug, 1/4" Pipe |

| 209-211 | A36240A | - | Cover, Front Bearing Assy. For -2 1/2" Shaft (Requires Oil Orifice in Item #214) |

| 209-211 | A36241A | A36241A | Cover, Front Bearing Assy. For 3" Shaft (Requires Oil Orifice in Item #214) |

| 212 | 31890A | 31890A | Gasket, Bearing Cover |

| 213 | 13159E | 13159E | Screw, 5/8" X 4" Socket Hd. |

| 214 | 31885A | - | Retainer, Front Bearing (w/oil hole) for 2-1/2" Shaft |

| 214 | 33500A | 33500A | Retainer, Front Bearing (w/oil hole) for 3" Shaft |

| 215 | 13152E | 13152E | Screw, 5/8" X 2" Hex. Head |

| 216 | 2796EV | 2796EV | Screw, 1/2" X 4" Hex. Head |

| 217 | A33483A | - | Seal, 2-1/2” Shaft Assembly |

| 217 | Check Model # (In Parentheses) | KT508: Shaft Seal & Gasket (All 440) | |

| 218 | Check Model # (In Parentheses) | KT509: Shaft Seal & Gasket (12-16 Cyl. 440, All 450XL) | |

| 219 | 2976EL | 2976EL | Screw, 1/2" X 1-3/4" Hex. Hd. |

| 220 | 31044A | - | Cover, 2-1/2" Shaft Seal |

| 220 | 32564A | 32564A | Cover, 3" Shaft Seal |

| 220A | 35078A | 35078A | Tube, Oil Drain |

| 224 | KT366 | - | Locknut, 2-1/2" Shaft |

| 224 | KT367 | KT367 | Locknut, 3" Shaft |

| 227 | KT368 | - | Front Bearing, 2-1/2" Shaft |

| 227 | KT369 | KT370 | Front Bearing, 3" Shaft |

| 228 | 33144A | - | Ring, 2 1/2" Shaft, Front Bearing Retainer |

| 228 | 33145A | 33145A | Ring, 3" Shaft, Front Bearing Retainer |

| 229 | Not Sold Separately | Crankshaft, Bare Shaft | |

| 224-244 | * | * | Crankshaft with Bearings |

| 231 | 31904A | 31904A | Retainer, Rear Bearing |

| 231A/231B | KT353 | KT353 | Rear Bearing and Lock Pin |

| 232 | 1736G | 1736G | Screw, 5/16" X 1-1/2" Hex. Hd. |

| 233 | 33403A | 33403A | Crank, Oil Pump Drive |

| 234 | A32163A | A32163A | Case, Bearing Support |

| 237 | 33508A | 33508A | Bearing Half, Upper Right or Lower Left |

| 238 | 33508B | 33508B | Bearing Half, Upper Left or Lower Right |

| 240 | 33497A | 33497A | Pin, Threaded Taper |

| 242 | 13165F | 13165F | Washer, 1/2" Lock |

| 243 | 1726E | 1726E | Nut, 1/2" Hex |

| 244 | 13253F | 13253F | Nut, 9/16" Hex. |

| 246 | 31994B | - | Key, 2-1/2" Crankshaft |

| 246 | 33505B | 33505B | Key, 3" Crankshaft |

| 247 | 31956A | 31956A | Screw Flywheel Hub |

| 248 | 33495A | 33495A | Washer, 3" Shaft, Flywheel Hub Screw |

* Check your Operator‘s Manual for correct Part Number for your specific compressor model. Splash shield included in crankshaft with bearings.

| Reference Number | Vilter Part Number | Description | ||

|---|---|---|---|---|

| 440 | 450XL | 450XL Booster | ||

| 501 | 31989M | 31989M | Piston Ring, Compression | |

| 502 | 31989N | 31989N | Piston Ring, Oil | |

| 503 | 33244A | - | Snap Ring, Piston Pin | |

| 501-505 | KT213 | - | Piston, Rings, and Pin Kit | |

| 501-512 | KT478 | KT573 | Piston, Rings, and Connecting Rod Assembly | |

| 506-512 | KT463 | - | Connecting Rod with Bearings | |

| 506 | 31896B | - | Bushing, Piston Pin | |

| 507 | See Kits Above | Connecting Rod | ||

| 509 | 2027A | 2027A | Nut, 3/8" UNF, Hex | |

| 510 | 2028A | 2028A | Nut, 3/8" Lock | |

| 511 | KT512 | KT575 | Bearing Set, Connecting Rod – Standard | |

| 511 | KT513A | KT399A | Bearing Set, Connecting Rod – 0 . 015" Undersize | |

| 511 | KT513 | KT399B | Bearing Set, Connecting Rod – 0 . 030" Undersize | |

| 512 | 31955A | 31955A | Bolt, Connecting Rod | |

| 513-518 | A32695C | - | Safety Head Assembly - Ammonia | |

| 513-518 | A32695D | - - | Safety Head Assembly - Halocarbon | |

| 513 | 1776B | - | 1776B | Nut 3/8" Lock Valve Retaining |

| 514 | 31990B | - | 31990B | Washer, Diaphragm Valve |

| 515 | 31939B | - | 31939B | Valve, Diaphragm Discharge |

| 515 | - | 35080SS | - | Plate, Discharge Valve |

| 516 | 31990A | - | 31990A | Spacer, Diaphragm Valve |

| 517 | 33531B | - | 33531B | Safety Head, Ammonia |

| 517 | 33532B | - | 33532B | Safety Head, Halocarbon |

| 517/522 | - | A35082A | - | Safety Head & Pins Assembly - Ammonia |

| 517/522 | - | A35272A | - | Safety Head & Pins Assembly - Halocarbon |

| 518 (a) | 31964A | - | - | Screw, Valve Retaining - 60° |

| 518 | 1527B | - | 1527B | Screw, Valve Retaining - 82° |

| 519 | 33803A | 33803A | 33803A | Spring, Valve |

| 520 | 31941B | - | 31941B | Yoke, Safety Head |

| 520/522 | - | KT543 | - | Safety Head Yoke and Pin Kit |

| 521 | 31882A | 35252A | 35252A | Spring, Safety Head |

| 522 | - | 1712F | - | Pin, 3/16" X 11/16" Roll |

(a) Applicable for compressors with serial number starting from 3638 thru 13490

| Reference Number | Vilter Part Number | Description | ||

|---|---|---|---|---|

| 440 | 450XL | |||

| 301-304 | KT092 | KT092 | Rear Bearing Cover Assembly | |

| 306 | KT519A | KT519A | Oil Pump Assembly | |

| 307-323 | KT256 | - | Conversion Kit, Std. Tri-Micro | |

| 309 | * | * | Cover, Oil Pump and Filter Head | |

| 310 | A35240A | A35240A | Tri-Micro Oil Filter Assembly with Bypass Relief | |

| 310 | - | - | Tri-Micro Oil Filter Assembly w/o Bypass Relief | |

| 311 | 1448J | 1448J | Spool, Internal with Bypass Relief | |

| 311 | - | - | Spool, Internal w/o Bypass Relief | |

| 312 | 1448H | 1448H | Seal, Spool End | |

| 313 | 1448K | 1448K | Strainer Tube | |

| 314 | 1448L | 1448L | Ring, Strainer Tube Retaining | |

| 315/321 | 1448C | 1448C | Oil Filter Element with Gasket for use with Bypass Relief | |

| 315/321 | - | - | Oil Filter Element with Gasket for use w/o Bypass Relief | |

| 316 | 1448M | 1448M | Pressure Plate Assembly | |

| 317 | 1448N | 1448N | Pressure Plate | |

| 318 | 1448P | 1448P | “O” Ring Seal, Pressure Plate (Not Shown) | |

| 319 | 1448Q | 1448Q | Spring, Pressure Plate | |

| 320 | 13264A | 13264A | Plug, 1/8" Pipe | |

| 321 | 1448B | 1448B | Gasket, Oil Filter Tank | |

| 322 | A34623A | A34623A | Filter Tank with Flange and Plug | |

| 323 | 2796DM | 2796DM | Screw, 7/16" X 2" Hex Head Cap | |

| 325 | 31890A | 31890A | Gasket, Bearing Cover | |

| 326 | 13152E | - | Screw, 5/8" X 2" Hex Head Cap | |

| 327 | 2796EL | 2796EL | Screw, 1/2" X 1-3/4" Hex Head Cap | |

* Check your Operator‘s Manual for correct Part Number for your specific compressor model.

| Reference Number | Vilter Part Number | Description | |

|---|---|---|---|

| 440 | 450XL | ||

| 401 | 32687A | 34510A | Liner, Cylinder (Single-Stage) |

| 401 | 33179A | 34710A | Liner, Cylinder (Integral Two-Stage) |

| 402 | 2176BH | 2176BH | Seal, “O” Ring, Upper |

| *402A | 2176BL | 2176BL | Seal, “O” Ring, Lower (Integral Two- Stage) |

| 403 | 1193Q | 1193Q | Pin, 1/8" X 1-1/2" Roll |

| 405 | A33351A | 35071A | Ring, Lift |

| 406 | 33352A | 35069A | Spring, Lift |

| 407 | 33350A | 35070A | Pin, Lift |

| 408 | - | 1971A | Retainer, Lift Ring |

| 409 | 31909A | 31909A | Plate, Suction Valve |

| 410A(a) | 31989L | - | Ring, Piston, Gas |

| 410B(a) | 2176AX | - | O-Ring, (Rubber-For 0.187” Groove) |

| 410C(b) | 2557A | 2557A | Ring, Gas |

| 410D(b) | 2639A | 2639A | Ring, Oil |

| 410E | 2638A | 2638A | Retainer, Snap Ring, Oil |

| 411A, 410C(c) | KT034 | - | Piston, Gas |

| 411B, 410D/E(c) | KT364 | - | Piston, Oil |

| 411C(d) | 35315A | 35315A | Piston, Gas or Oil |

| 412 | 33250C | - | Pin, Long Pivot |

| 413(e) | 33338A | - | Arm, Yoke Lifting |

| 413A(e) | 41725A | 41725A | Arm, Yoke Lifting (New Style) |

| 414 | A33335A | A33335A | Yoke Assembly, Std. Unloading |

| 414 | A33575A | A33575A | Yoke Assembly, Single Cyl Unloading |

| 415 | 1193X | 1193X | Pin, 3/8" X 11/16" Roll |

| 416 | 33250B | 33250B | Pin, Short Pivot |

| 417 | 33686A | 33686A | Spring, Unloader Yoke |

| 418 | A33347A | A33347A | Yoke Guide, Std. Unloading |

| 418 | A33576A | A33576A | Yoke Guide, Single Cyl Unloading |

| 419 | 1352D | 1352D | Screw, 3/8" X 1" Hex Head Lock, Single Cyl Unloading |

| 420 | 33618A | 33618A | Spacer, Sleeve, Single Cyl Unloading |

(a) 410A and 410B- Sold for replacement use only; will not fit present pistons.

(b) 410C and 410D- Not interchangeable with 410A and 410B used on compressor serial numbers below 3638.

(c) 411A and 411B- Present pistons cannot be used with rings kit used for compressor serial numbers below 3638. KT034 contains 410C; KT364 contains 410D/E.

(d) 411C- New piston, used on compressors with serial number starting from 32500 for gas unloading & from 22800 for oil unloading, is not interchangeable with piston (pre 1985 year) used on compressors serial number starting from 19247 thru 22799 for oil unloading and from 3638 thru 19246 & 30000 thru 32499 for gas unloading (requires different frame). New piston has two grooves- top for gas and bottom for oil.

(e) 413 and 413A- Yoke lifting arms not interchangeable.